http://www.peerintal.co.jp/en/

Peer International Limited

Central Kyobashi Bldg., 1-4-13

Kyobashi, Chuo-Ku,

Tokyo 104-0031, Japan

Kyobashi, Chuo-Ku,

Tokyo 104-0031, Japan

TEL:+81-3-6665-6491 (Administration)

FAX:+81-3-6665-6498

FAX:+81-3-6665-6498

003229

PRODUCTION PROCESS OF PIG IRON

- HOME >

- PRODUCTION PROCESS OF PIG IRON

| Sintered Iron Ore | Sintering iron ore fines and limestones at high temperature |

| Coke | High-purity carbon chunk with heating metallurgical coal at high temperature |

2.Production Process of Pig Iron

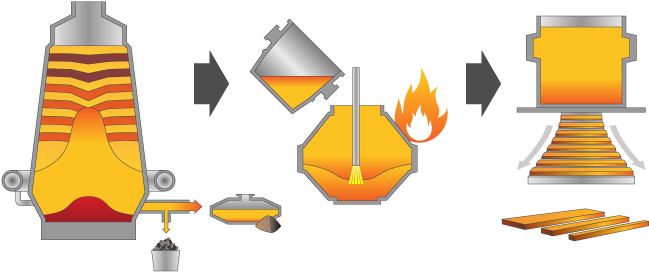

When the interior of blast furnace with alternately placing sintering ore and coke is brought into a high temperature state (2,000°C or higher) by blowing hot air from the bottom part, iron (pig iron) is reduced and separated from sintered ore by chemical reaction, and various impurities (slag) contained in sintered ore are also removed.

3.Process of Steelmaking

Pig iron carried from the blast furnace and steel scrap are charged into a converter, then the high-pressure oxygen is blown into the converter to remove unnecessary carbon and the other impurities. After the process, steel (iron with carbon content less than 1.7%) is made by adjusting the ingredients.

4.Continuous Casting

Continuously flow steel in the molten state into the mold according to the shape and weight of the final product, gradually cool it with water, pull out the solidified steel with a roll and cut it.

The resulting lump of steel is called "semi-finished casting products" and can be divided into three types, "blooms", "billets" and "slabs", depending on the shape of the final product.